About Us

Zhejiang Ankor Electric Co., Ltd.

E-ankor company: manufacturer

Background: 12700㎡ factory area, 60% automation facility and more than100 employees.

Strength: more than 30 years’ rich experience in R&D technology and in manufacturing of products.

Compliance: security compliance certifications, such as CE,ROHS,UL,FCC,3C, and quality management system certifications, such as ISO9001:2015 and IATF16949:2016.

Products range: automobile maintenance tools, such as battery charger, jump starter, battery analyser.

Exporting markets: EU,USA,UK, RU, Africa, Asia,etc

Main business model: BRAND SPECIAL CUSTOMIZATION

Welcome To Ankor

Years Of Experience

About Us

Exported markets: 20+

Cooperation customers: 50+

Brand customization projects: 30+

E-ankor vision:

B. To supply diversified customized products.

C. To provide one-stop service (development, manufacturing, supply and after-sales service.)

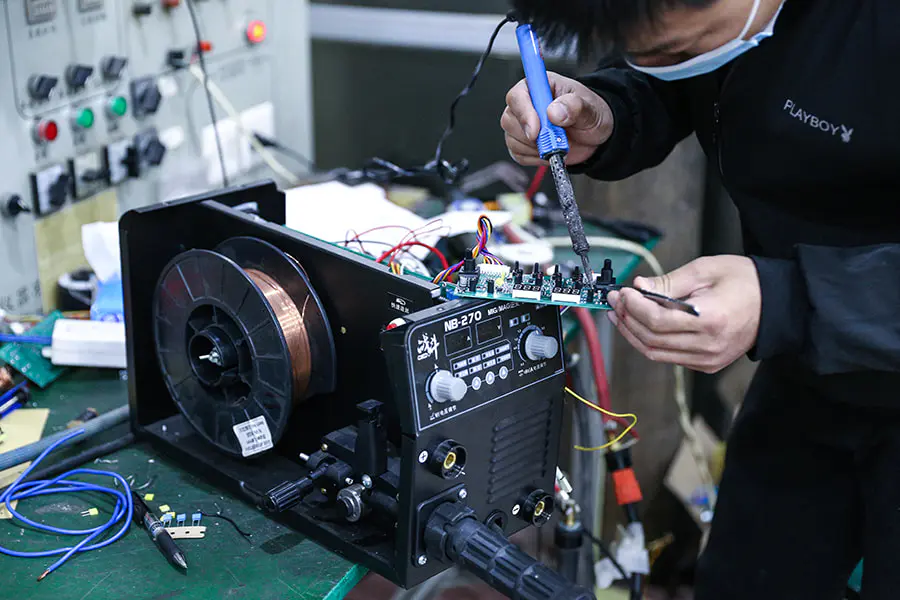

FACTORY DISPLAY

VISIT OUR FACTORY

We always adhere to the corporate goal of “high standard, refinement, and zero defect”, regard quality as our life, lead the development of the industry, and create an electromechanical enterprise with core competitiveness and core value.

FACTORY DISPLAY

OUR FOOTPRINTS

ARE AROUND THE WORLD

We provide quality products and services to customers from all over the world

OUR 3 STEP DESIGN PROCESS

How it works

Below is our simple end-to-end process all our customer’s projects go through.

The below process is a standard at Zhejiang Ankor Electric Co., Ltd. as it allows us to drill into exactly what it is you need for your applications, how we can help you achieve that, and finally deliver it to you, all direct from our world-class manufacturing facility.

1. EXPLORE

We like to discuss our customer’s unique applications. Our team can help you consider the technical decisions at the product level and show you how we can provide an efficient design-phase and production ramp-up.

2. QUOTE

Fully transparent costings are laid out for you with a clear timeline for each step of your project. Cell selection, electronics features, and mechanical requirements are all covered to ensure full compliance to your specification.

3. SUPPLY

We work through strict design and manufacturing stage-gates to guarantee adherence to the agreed specification for each unique battery. Verification and validation stages, and approvals lead us to tooling, then battery certification before production starts. Once in full production, our On-Time-In-Full delivery success is >98%.